VSL

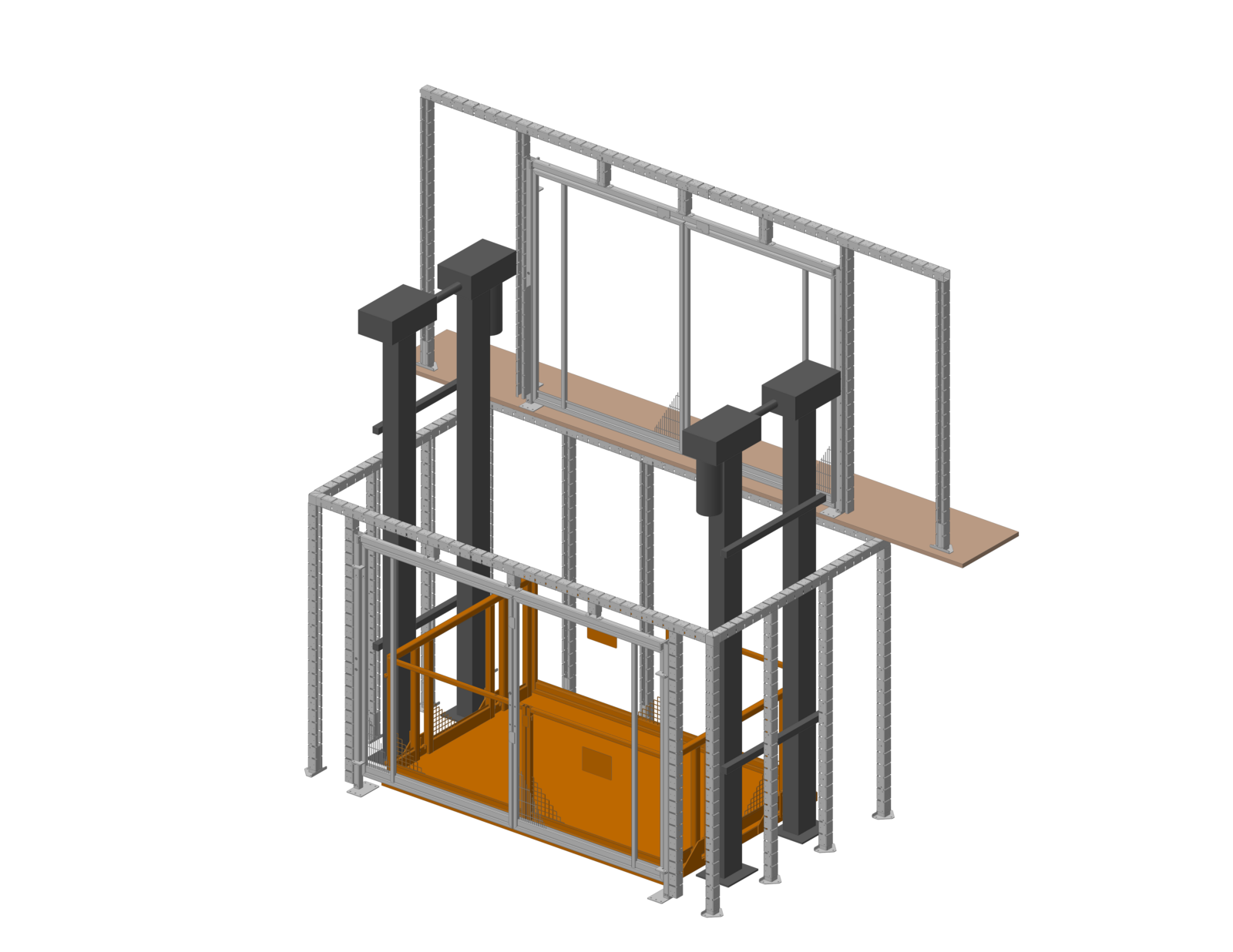

Four column lift for demanding industrial applications

payload up to 3000 kg

The VSL is a 4-column lift system that ascends a cage, platform, or customized device (frame, hoist). The columns are arranged in pairs opposite each other. And that either on the short or long basket sides, since the platform does not run through any drive elements! With this unique feature, the possibilities are practically endless! The VSL has a maximum payload of 3000 kg and can be configured for lifting heights of up to 12 m.

-

A large number of load handling devices with variable platform widths and lengths allow a large selection. The statics are the only limitation. Platform lifts, cycle stations, jig structures and more can be implemented. With conventional hoisting cages, the cage enclosure has a standard height of 1100 mm with a stable welded mesh filling. The cage access doors are positioned according to customer requirements and of course integrated into the lift control with limit switches. Larger basket enclosures up to a complete conveyor cage are also possible in a variety of ways. The systems can also be integrated into production processes.

Such systems always result from close consultations between the customer and our experts. We build your individual material lift. Talk to us!

By default, the VSL is designed as a fully enclosed, self-running lift system. Each floor has appropriate landing doors and all required fixed enclosures of machine guards. The storey doors are system-integrated and can only be opened when the hoisting cage is in front of it, thanks to an electric safety lock.

-

Manufactured in accordance with Machinery Directive 2006/42/EG and DIN EN 81/31 for accessible goods lifts including all storey access doors and necessary enclosures made of machine guards.

- safety gear

- Duplex chain drive with 4x safety factor

- Electromechanical engine brake

- chain tension sensor

- electrically locked landing doors

- active overload protection

- upper emergency limit switch;

- thermal motor protection;

-

An extensive range of equipment enables you to have your lift system perfectly tailored to your needs!

Excerpt from our equipment program:

- Custom cage sizes in 100mm increments

- A large variety of drive-on ramps to the high-floor baskets (as a fixed floor ramp or mobile folding ramp) or pit installation for a ground-level entrance (pit depth 120 mm)

- Additional or differently arranged cage doors (single leaf or double leaf)

- Special basket openings, if necessary Loading and unloading around the corner

- Increasing the cage protection up to 2000 mm

- a large variety of floor doors with other opening types (sliding doors, roller doors, high-speed roller doors) to match the conveyor basket doors;

- increased lifting speed (8,4 m / min.) With soft start, soft stop;

- Additional visual signaling

- Integration of the system into an external controller

and much more…

-

BASIC TECHNICAL SPECIFICATIONS

feature Value unity Tragfähigkeit max. 3000 kg number of floors max. 6 Control Automatic control with control points on all floors Lifting height to 12.000 mm Lifting / lowering speed (standard) standard 4,2 (optional 8,4) m / min. Minimum conveyor cage length (external dimension) 1700 mm Maximum conveyor cage length (external dimension) 6000 mm Minimum conveyor cage width (external dimension) 1700 mm Maximum conveyor cage width (external dimension) 4000 mm Enclosure height conveyor cage 1100 – 2000 mm Horsepower 2 x 4,0 kW Control voltage 24 V Protection IP 54 to IP 66 Connection values 400V (3PH+N+PE/50Hz) Start-up mode Soft start / soft stop Motor data S1 motor (continuously running) Conveyor cage / means Customizable in 100mm increments -

Advantages that convince!

- Simple planning thanks to our modular building block system

- Space-saving and low-wear chain drive

- No special structural work required

- Ramp or low pit depth (120 mm)

- Infinitely variable lifting height adjustment up to 12 m

- All column lifts are designed for continuous operation (S1 motor)

- Electro-mechanical drive (gear motor + chain)

- No separate machine room required;

- Very quiet running

- No trained staff required (comparison forklifts)

- Reduces absenteeism due to accidents and illness

- Low maintenance

- Can be set up outdoors

Gallery

3D model

Augmented Reality

Visualize the VSL in your environment!

- Scan QR code with a smartphone or tablet (click QR code to enlarge)

- Place VSL in space

- View from all sides

3D model

Augmented Reality

Visualize the VSL in your environment!

- Scan QR code with a smartphone or tablet (click QR code to enlarge)

- Place VSL in space

- View from all sides