About WEP-Weisshaupt Experience meets innovation

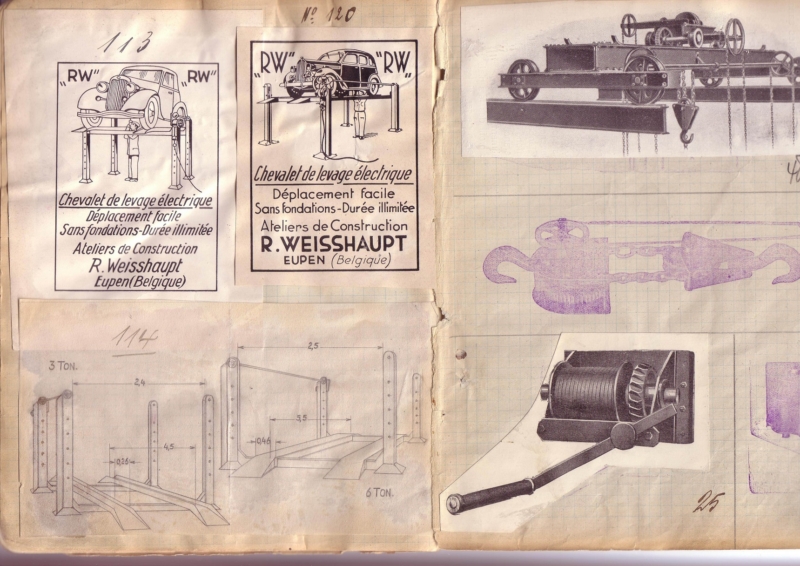

In 1868 the brothers Nikolaus and Mathias Klinkenberg founded the Klinkenberg locksmith's shop. The company started out as a repair shop, manufacturing spare parts and accessories for textile machines. With the rise of the textile industry in the region, the locksmith's shop became a reliable supplier for large textile companies. Over time, the company expanded its offer to include machines for the textile industry and specialized in the production of hoists and lifting platforms.

Production was curtailed during World War II, but after the war the company rebuilt its business and became a major supplier to the automotive industry. The company continued to diversify and began manufacturing insulating tubes for electrical cables. Today, R. Weisshaupt AG is an established company with a wide range of metal processing and elevator solutions.

Our story

1987

Airfreight

We have also been active in the air freight sector since 1987.

1972

lifts

After the need for manual hoists had also fallen sharply since 1972, the company decided to stop producing them.

In the same year, the Quicklift 2,5t lift was developed, which stood out with its double lifting speed compared to the previous 3,5t lift. After the Quicklift lift with a lifting capacity of 5t was added to the product range, the company stopped manufacturing the "standard" 3,5t lift, as sales had plummeted due to the new technology.

The lift business has grown steadily and has become one of our mainstays over the years. There were also other metal processing such as:

- Semi-automatic welding of iron, aluminum and stainless steel

- Sheet metal cutting work on machines up to 3000 x 6 mm and plasma cutters up to 200 mm; for larger strengths with Secator

- Sheet metal edging on a 150 t press (the pillars of all lifting platforms and the traverses and rails of the platforms up to 5 t are produced with it)

- Filming of all kinds

- Milling of gears from module 2 to 10 and up to 900 mm diameter

- Other milling, planing and grooving work

1969

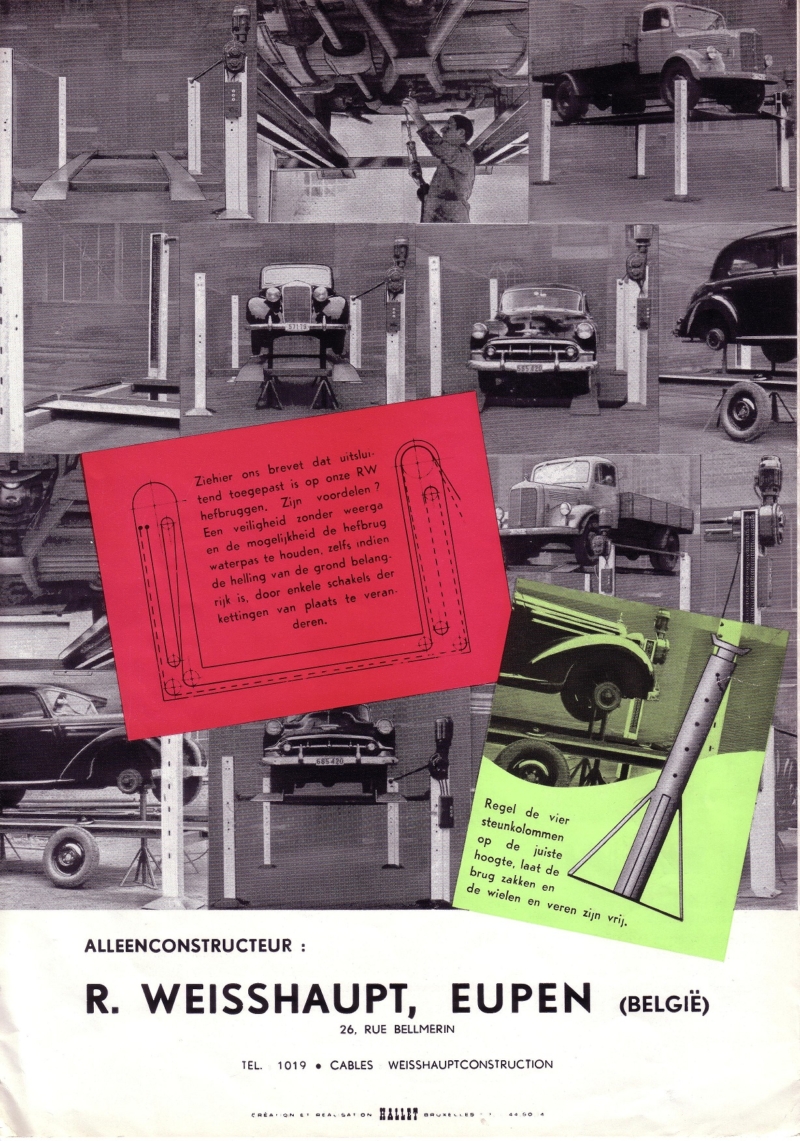

Two column lifts

The need for hand hoists, for which the chains were mainly used, decreased more and more. The production was no longer worthwhile and the chain department was shut down. We bought the chains that were still needed for a while from a friendly factory.

From now on we started the production of 2-post lifts, of which approx. 400 pieces were made.

1960

Automotive industry

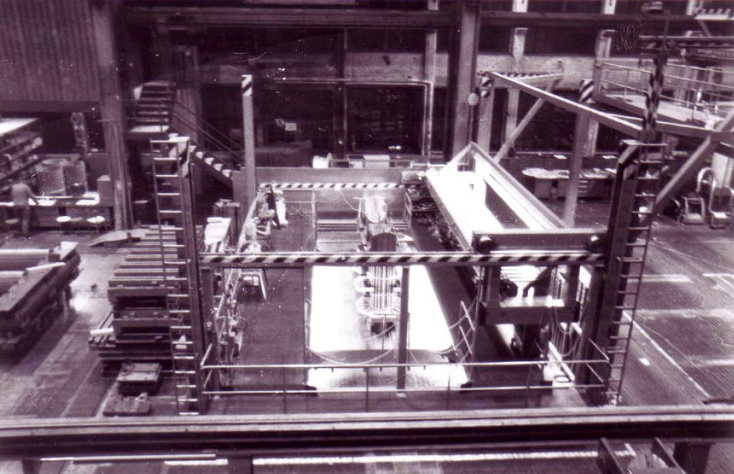

In 1960 the European Ford headquarters in Cologne began to build a plant in Genk/ Belgium for around 9000 employees. Through the local Chamber of Commerce, Ford looked for Belgian suppliers for factory equipment. The contract was signed and since then R. Weisshaupt AG has mainly supplied and assembled the superstructure and conveyor systems above the workplaces and assembly chains of the vehicles. These were attached to the 8-9 m high roof construction and came down up to 3 m above the hall floors. The main plant in Cologne-Niehl and the plants in Cologne-Merkenich, Saarlouis and Düren were constantly enlarged or modernized. So that R. Weisshaupt AG could also deliver this iron construction here. In addition, there were countless custom-made lifting devices, etc., each adapted to the needs. In addition, there were two complicated devices we developed for Düren for lifting, turning and translating gearbox housings. We also supplied and assembled the same equipment for Ford's English transmission plant in Halewood near Liverpool.

1945 - 1959

Special lifting platforms

Due to the strong backlog due to the war, manual hoists were mainly manufactured for the domestic market for several years. Gradually, exports to various European countries and to the Congo, which was still a Belgian colony at the time, increased.

There were also electric traveling cranes equipped with electric trolleys or winches from Demag.

At the same time, more and more special lifting platforms were produced. From 6t to 14t for forklifts and other short, heavy vehicles and later also 6-post lifting platforms for extra long vehicles such as articulated buses, articulated trucks, etc.

1945

end of the second world war

At the end of the war, the area of Eupen, Malmedy and St.Vith changed nationality again and was assigned to Belgium as compensation.

1940 - 1945

Chaos of war

During the Second World War, the Belgian border area was again incorporated into Germany. The production of hand hoists continued, as did the manufacture of aerial platforms, but on a smaller scale.

1935

Higher lifting capacities

After the need for gravure presses had dropped significantly, the company reoriented itself.

In 1935 the first vehicle lifting platform with a lifting capacity of 3t was built. More than 3000 of this type were built. Other types with higher lifting capacities of 6t, 7,5t and 12t followed.

1932 - 1936

Platen presses

Several hundred platen printing presses for the English colonies (mainly for India) were sold and delivered to a London company.

1924

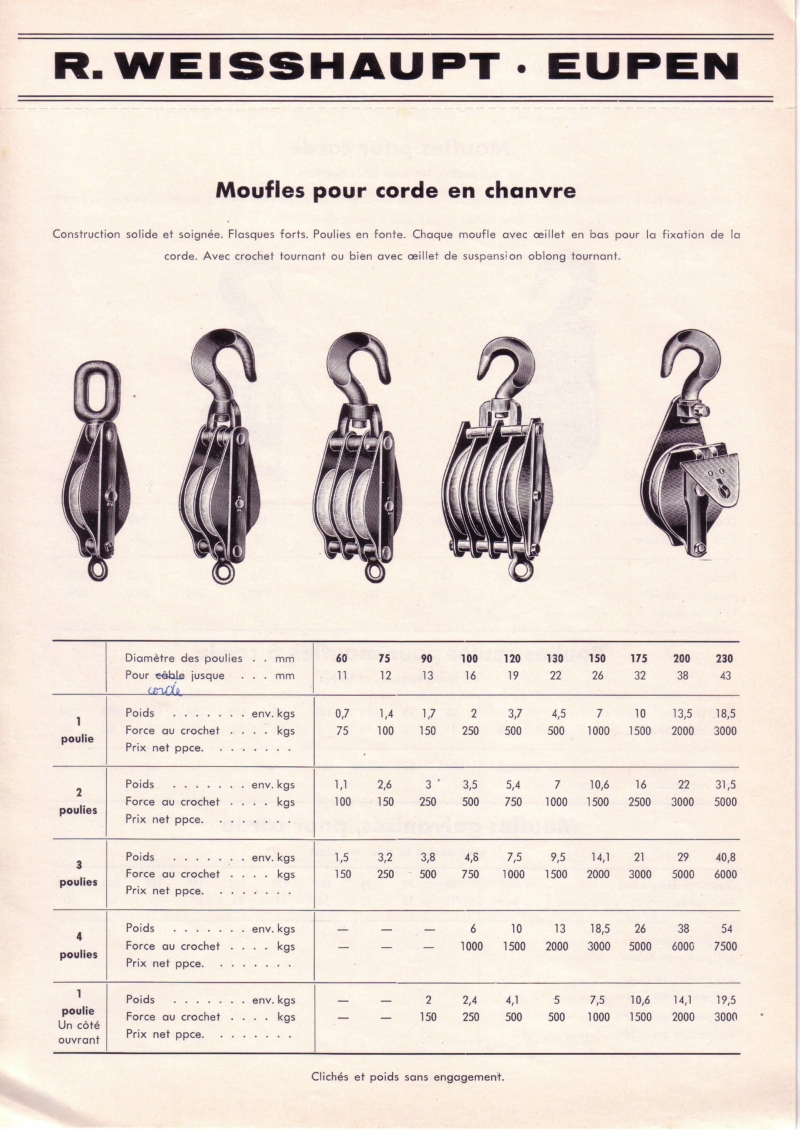

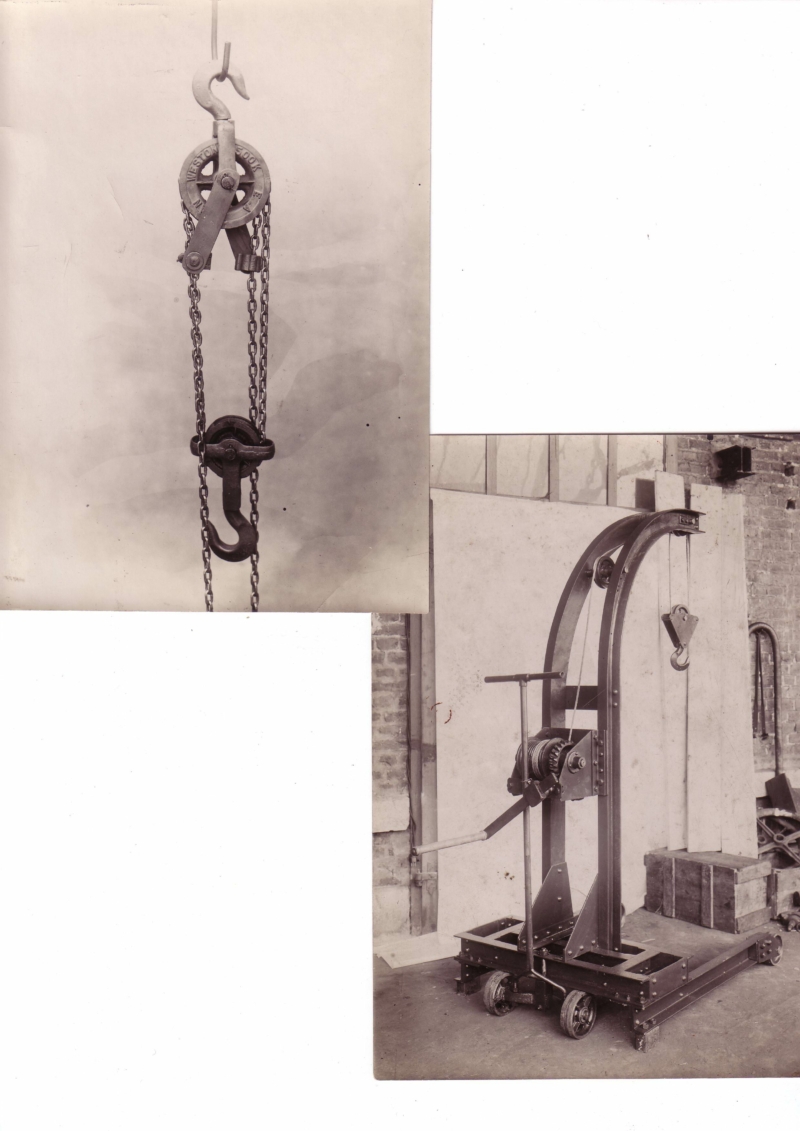

Chain production

A separate department for the production of chains was set up, which could produce electrically welded chains between 4mm and 13mm material diameter.

1922

Hand hoists

The company continues to expand its product range: the manufacture of hand hoists.

A few years later, the production of handrail cranes was introduced, which could lift up to 15t with a possible track width of 15m.

1914 - 1918

Business language French

The war also brought all sorts of difficulties here in the border area. With the Peace Treaty of Versailles, the previously German territory here was incorporated into the Kingdom of Belgium. The business language was now French and brought with it all sorts of changes that had to be mastered.

1910

Insulating pipes

A new segment was introduced: the first machines for the production of insulating tubes for electrical cables were built. The workforce grew.

1906

Marine engines

Reiner JF WEISSHAUPT takes over the company. For years he was the first mechanic at Deutz-Gas-Motoren (predecessor of diesel engines). At that time, canal ships were more and more equipped with these engines. Reiner JF Weisshaupt often drove the ships for weeks to monitor the running-in of the engines and to teach the customers how to use the new technology, which was still quite unknown at the time. He continued the core business of the Klinkenberg brothers with the staff he had taken over.

1868

Machines for the textile industry

The brothers Nikolaus & Mathias KLINKENBERG found the locksmith Klinkenberg. At that time, the core business consisted of the production of spare parts and accessories, as well as the repair of machines for numerous large textile companies in the surrounding cities. Eupen and the area around the Weser River were the center of the wool industry at the time.